Epson's Accelerometers Features and Lineup

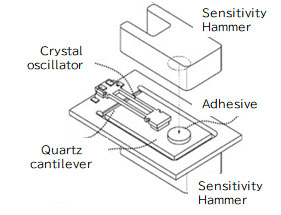

#1 - Acceleration Detection Devices Using Quartz

Thermal expansion coefficient differences between parts are eliminated because the bi-tuning fork resonator and cantilever inside the sensor are made of quartz crystal which suppresses sensitivity changes due to temperature changes. This minimizes changes in sensitivity due to temperature.

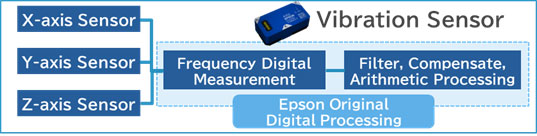

#2 - Digital Data Value Output

Epson use frequency digital measurement IP that eliminates analog circuits to the maximum extent possible, and our unique digital frequency detection method enables high-precision, wide-band acceleration detection. It also comes equipped with highly convenient filter compensation and calculation processing functions.

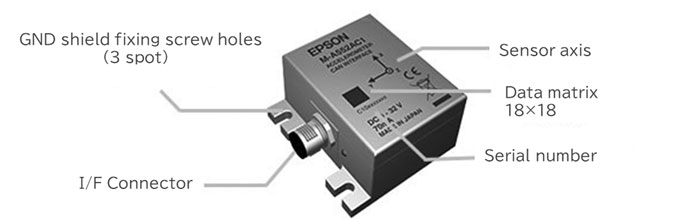

#3 - Digital Data Value Output Enables Sensor Control From PC

Epson's accelerometers directly output measurement data as digital values. This digital I/F allows direct connection to a PC via general-purpose I/F hardware and control of the sensor from the PC. Using any preferred programming environment, users can build custom sensor systems or integrate the sensors into existing systems. In contrast, analog sensors require connection to a PC through a PLC's A/D unit or an external A/D converter. While dedicated software is often available for handling analog sensor data, customizing or adding them to existing systems can be more challenging.

#4 - Low Noise, High Resolution, Wide Detection Range, High Stability

Highly stable crystal sensor element realizes noise performance better than 1μG/√Hz and wide detection range. Proprietary noise-resistant direct digital conversion technology enable digital output of 3-axis acceleration data with high resolution of 0.06uG/LSB enables determination of minute displacement angle, long-period vibration, and displacement magnitude. Realize 1,000G shock resistance and ideal for applications requiring highly accurate measurements such as structural health monitoring, seismic and environmental vibration.

Note: The impact resistance of the M-A352 and M-A552 is 1,000 G. The M-A370 has an impact resistance of 500 G. For details, please refer to the datasheet.

#5 - Acceleration Measurement and Analysis in a Slim System Configuration

Epson's accelerometers are compact and, unlike analog sensors, do not require a PLC A/D unit or an external A/D converter. This enables cost-effective acceleration measurement and analysis by reducing the total system cost.

#6 - Waterproof and Dustproof Unit

M-A552 is a waterproof and dustproof acceleration sensor equivalent to IP67 using a built-in M-A352. Ideal for use in harsh environments such as outdoor installation.

Documents about the basics and usage of accelerometers

You can download documents of the basics, selection, and usage of accelerometers.

13 items to consider when selecting accelerometer and 4 items of particular importance

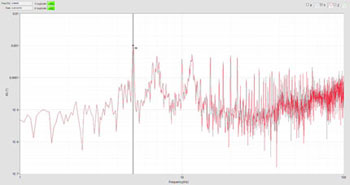

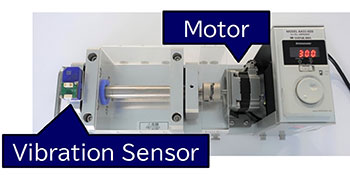

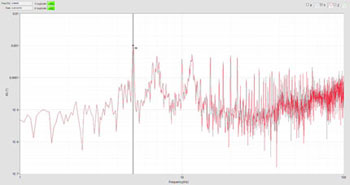

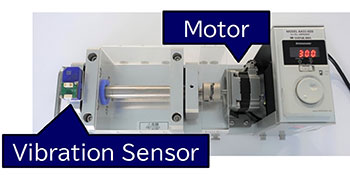

Measurement data and analysis of low-speed rotation device with an accelerometer

Measurement data and analysis of bearing deterioration with an accelerometer

Measurement data and analysis of the World's Largest Caldera, Mt. Aso with an accelerometer

Epson's Accelerometers Lineup

Documents about the basics and usage of accelerometers

You can download documents of the basics, selection, and usage of accelerometers.

13 items to consider when selecting accelerometer and 4 items of particular importance

Measurement data and analysis of low-speed rotation device with an accelerometer

Measurement data and analysis of bearing deterioration with an accelerometer

Measurement data and analysis of the World's Largest Caldera, Mt. Aso with an accelerometer