What are Vibration Sensors?

A vibration sensor is a device that detects the vibration of physical objects. Vibration can be represented by physical quantities such as displacement, velocity, and acceleration. The appropriate quantity is typically selected based on the characteristics of the vibrating object and the frequency range involved.

| Displacement | Ideal for detecting natural vibration of structures and unbalance of low-speed rotating equipment. Vibration frequency is mainly below 100 Hz. |

|---|---|

| Velocity | Ideal for detecting motors unbalance. Vibration frequency ranges from 10 to 1,000 Hz. |

| Acceleration | Ideal for detecting bearing damage. Vibration frequency is 1,000 Hz or higher. |

Vibration sensors are used not only in production equipment and civil engineering structures, but also in research and development fields. In manufacturing, they are employed for predictive maintenance by detecting early signs of wear or damage in equipment such as motors and bearings, helping to prevent unexpected downtime. In recent years, advancements in data analysis, combined with vibration sensors and IoT devices, have enabled early detection of anomalies, contributing to improved production efficiency by reducing downtime and repair costs. In research and development, vibration sensors have long been used in product design and durability testing. They are widely applied across various industries, including automotive, railway, electrical equipment, and industrial robotics.

Documents About Features and Functions of Epson's Vibration Sensors

You can download documents of the basics, selection, and usage of vibration sensors.

What is an vibration sensors?

You can download a document explaining the basics, features, and main applications of Epson's vibration sensors.

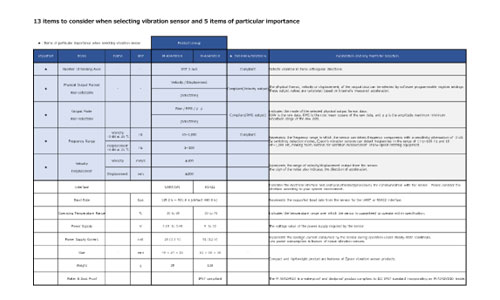

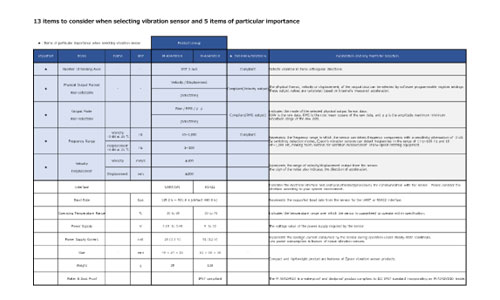

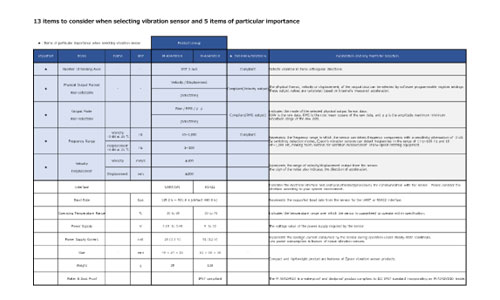

How to compare vibration sensor

You can download a document that explains 13 items to consider when selecting an IMU, with particular emphasis on 5 key items.

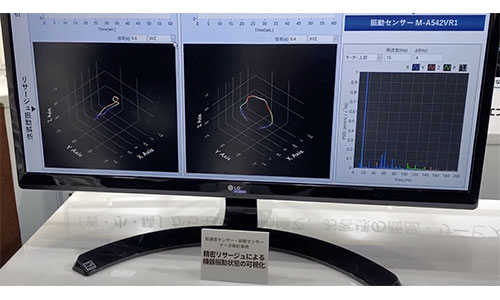

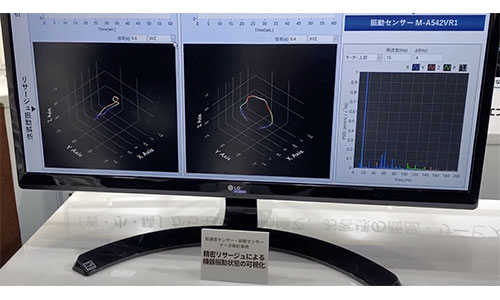

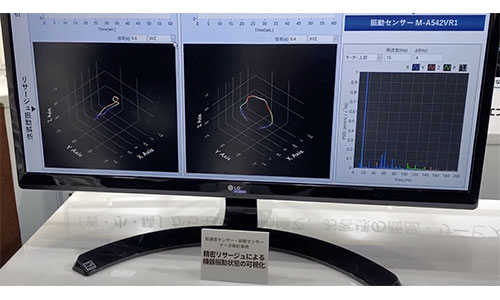

Measurement data of bearing deterioration

This document provides data from actual measurements showing the difference in vibration based on the presence or absence of damage to bearings.

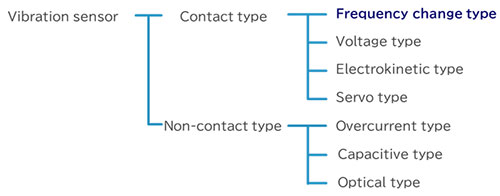

Types of Vibration Sensors

Vibration sensors come in two types: contact and non-contact. It is important to select the appropriate type of sensor based on the measurement location and the characteristics of the vibration.

Epson's vibration sensors are contact-type devices that utilize a frequency-based acceleration sensor.

By internally processing the measured acceleration, these sensors can convert and output the data as vibration velocity or displacement.

This method calculates the distance between the sensor and the target object based on the change in capacitance between them.

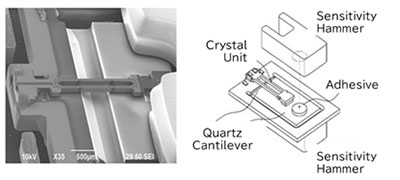

How Vibration Sensors Work

The basic structure of Epson's vibration sensor consists of a crystal unit, a quartz cantilever, and a sensitivity hammer. When vibration is applied, the quartz cantilever and the sensitivity hammer convert the vibration into tensile or compressive force on the crystal unit. This force causes a change in the resonator's oscillation frequency. The oscillation frequency, which varies according to the magnitude of the vibration, is then converted into physical quantities such as acceleration or velocity, and output as digital values from the sensor.

Documents About Features and Functions of Epson's Vibration Sensors

You can download documents of the basics, selection, and usage of vibration sensors.

What is an vibration sensors?

You can download a document explaining the basics, features, and main applications of Epson's vibration sensors.

How to compare vibration sensor

You can download a document that explains 13 items to consider when selecting an IMU, with particular emphasis on 5 key items.

Measurement data of bearing deterioration

This document provides data from actual measurements showing the difference in vibration based on the presence or absence of damage to bearings.

Differences Between Accelerometers and Vibration Sensors

The term "vibration sensor" refers to a sensor named after the phenomenon it detects, while "acceleration sensor" is named after the physical quantity it measures.

Vibration sensors may incorporate displacement sensors or acceleration sensors, and are capable of detecting both the magnitude of vibration (displacement, velocity, acceleration) and its periodicity (frequency).

Acceleration sensors can measure periodic acceleration acting on an object and constant (DC) acceleration such as gravitational acceleration.

Epson's vibration sensors use accelerometers and convert measured acceleration into vibration velocity and displacement by internal calculations.

| Accelerometer | Detected Phenomena | Vibration, tilt, linear motion, resonant frequency of structures |

|---|---|---|

| Detected measurement | Acceleration | |

| Vibration sensor | Detected Phenomena | Vibration (shaking of object) |

| Detected measurement | Acceleration, velocity, displacement |

Documents About Features and Functions of Epson's Vibration Sensors

You can download documents of the basics, selection, and usage of vibration sensors.

What is an vibration sensors?

You can download a document explaining the basics, features, and main applications of Epson's vibration sensors.

How to compare vibration sensor

You can download a document that explains 13 items to consider when selecting an IMU, with particular emphasis on 5 key items.

Measurement data of bearing deterioration

This document provides data from actual measurements showing the difference in vibration based on the presence or absence of damage to bearings.