Epson's Vibration Sensors Features and Lineup

#1 - Compliant with ISO10816/ISO20816

Epson's vibration sensor is a three-axis vibration sensor that digitally outputs velocity and displacement and complies with ISO10816/ISO20816, which defines procedures and guidelines for measuring and classifying mechanical vibrations.

#2 - Simultaneous 3-Axis Detection Enables Leak-Free Detection

It is difficult to determine the magnitude and direction of vibrations generated by motors and other devices through visual inspection, as these characteristics can vary from one device to another.

Sensors that can only detect vibration along a single axis may fail to capture vibrations that occur in other directions.

Epson's vibration sensor is equipped with three detectors with uniform characteristics, which operate in parallel. This allows for the precise acquisition of phase-aligned, three-axis data, making it ideal for advanced vibration analysis that utilizes phase information.

#3 - Digital Data Value Output Enables Sensor Control From PC

Epson's vibration sensors directly output measurement data as digital values. This digital I/F allows direct connection to a PC via general-purpose I/F hardware and control of the sensor from the PC. Using any preferred programming environment, users can build custom sensor systems or integrate the sensors into existing systems. In contrast, analog sensors require connection to a PC through a PLC's A/D unit or an external A/D converter. While dedicated software is often available for handling analog sensor data, customizing or adding them to existing systems can be more challenging.

#4 - High Resolution and Wide Detection Range

Since equipment such as motors generate a variety of vibrations ranging from slight to strong vibrations, vibration sensors need to have a wide detection range that covers both slight and strong vibrations. General vibration sensors, however, have a trade-off relationship between resolution and detection range.

Epson's vibration sensor combines high resolution with a wide detection range, based on a unique detection principle using quartz crystals. Epson's vibration sensors are accurate with an error of less than 1%, while typical analog vibration sensors contain errors of up to 10% in measurement values.

#5 - Slim System Configuration for Vibration Measurement and Analysis

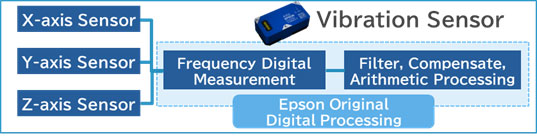

By minimizing the use of analog circuitry, Epson's vibration sensors employ a frequency-based digital measurement IP that enables high-precision, wide-bandwidth acceleration detection through a proprietary digital frequency detection method. They are also equipped with advanced features such as convenient filter compensation and built-in signal processing functions. Digitalization of the signal inside the sensor and as a signal output makes it highly resistant to noise.

#6 - Waterproof and Dustproof Unit

Waterproof and dustproof construction enables use in applications requiring environmental protection characteristics. Ideal for use in harsh environments such as outdoor installation. M-A542 is a waterproof and dustproof vibration sensor equivalent to IP67 using a built-in M-A342.

Documents about vibration sensor usage (measurement and analysis)

You can download documents summarizing vibration sensor measurement and analysis methods.

Measurement data and analysis of low-speed rotation device with an accelerometer

Measurement data and analysis of bearing deterioration with an accelerometer

Epson's Vibration Sensors Lineup

Documents about vibration sensor usage (measurement and analysis)

You can download documents summarizing vibration sensor measurement and analysis methods.

Measurement data and analysis of low-speed rotation device with an accelerometer

Measurement data and analysis of bearing deterioration with an accelerometer