Machine Condition Monitoring System based on ISO 20816

Overview

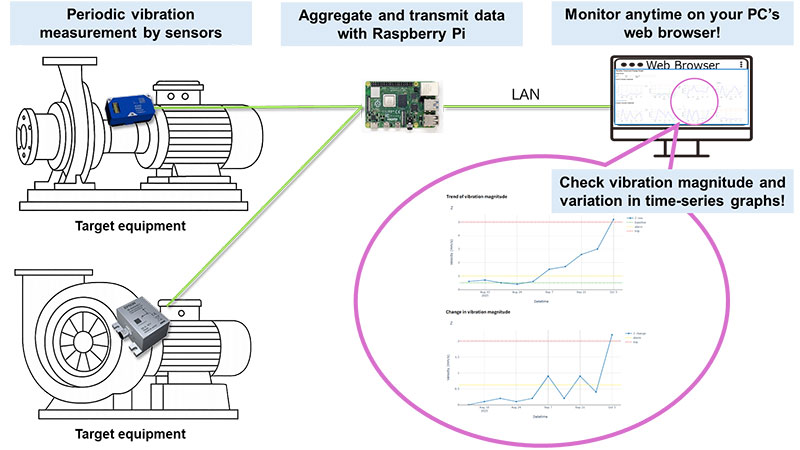

This system is an application that enables vibration-based machine condition monitoring in compliance with ISO 20816. It works in Raspberry Pi with a vibration measurement system. It performs statistical processing and time-series analysis on data acquired from acceleration/vibration sensors to visualize the health of rotating machinery.

What is ISO 20816?

ISO 20816 is an international standard that defines methods for machine condition monitoring using vibration. It recommends periodic measurement of machine vibration and monitoring of its magnitude, rate of change, and variation speed. If monitored values exceed predefined thresholds, emergency shutdown or maintenance actions are required.

For example, a household washing machine may become noisier over years of use compared to when it was new. This is often due to abnormalities such as shaft misalignment caused by long-term operation, resulting in increased vibration. In such cases, repair or replacement is necessary. Similarly, monitoring vibration levels in rotating equipment used in production facilities provides critical clues for detecting abnormalities.

Monitoring not only vibration magnitude but also changes over time is essential. Under consistent operating conditions, vibration levels should remain stable. Even if values are within normal limits, a sudden change compared to previous measurements may indicate an underlying issue that requires close attention.

This system enables ISO 20816-compliant condition monitoring using Raspberry Pi and Epson acceleration/vibration sensors.

Key Features

- Compact and Energy-Efficient: Raspberry Pi and digital-output sensors allow for a space-saving measurement setup suitable for factory environments.

- Automated Calculation and Evaluation: Periodic measurements are processed to calculate vibration magnitude (RMS) and variation, automatically determining machine status based on threshold values.

- Customizable: Python-based aggregation programs can be tailored for specific frequency bands or alternative indicators beyond RMS, enabling monitoring adapted to your environment.

- Multi-Axis Support: Each sensor provides three-axis (X, Y, Z) vibration data and combined values for comprehensive monitoring.

- Multi-Point Monitoring: Multiple sensors can be deployed to monitor several machines or locations.

- Web-Based Visualization: Aggregated results and alerts can be monitored via a web browser.

Monitoring on Web Browser

Condition monitoring focuses on vibration magnitude, its variation, and the rate of change.

This system provides both trend graphs (showing vibration magnitude changes) and variation graphs (showing differences between consecutive measurements) on a single browser screen.

Trend Graph

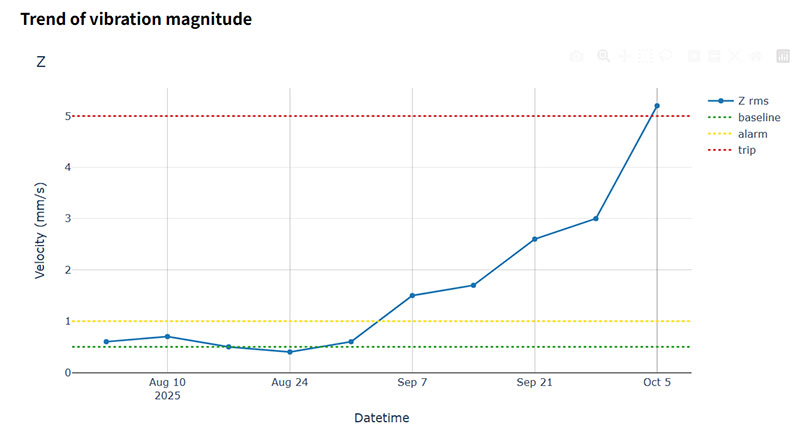

Graphs display changes in vibration magnitude (RMS) for each axis and combined values. Baseline values and threshold levels (alarm and trip) can be overlaid for quick visual assessment when measurements exceed limits.

(The image above illustrates a view displaying only the Z-axis. The values shown are for reference and do not represent actual measurements.)

Variation Graph

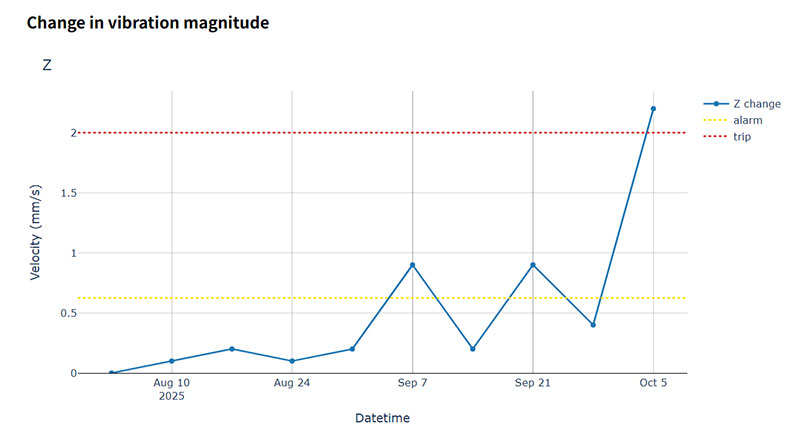

Monitoring variation is critical for early anomaly detection. This system calculates differences between current and previous measurements and displays them in a variation graph. The slope of the graph indicates the rate of change.

(The image above illustrates a view displaying only the Z-axis. The values shown are for reference and do not represent actual measurements.)

System Configuration

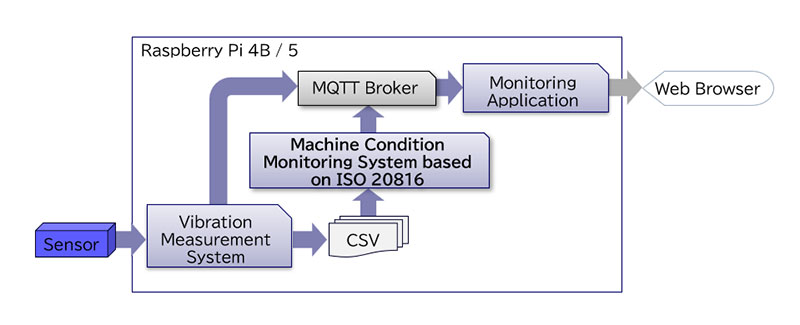

The system consists of three main components:

- Vibration Measurement System

- Machine Condition Monitoring System based on ISO 20816

- Monitoring Application

Component

Vibration Measurement System

Vibration measurement system uses acceleration/vibration sensors to measure machine vibration and outputs data as CSV files.

The vibration of the target equipment is measured using vibration and acceleration sensors, and the data is output as a CSV file. Measurement timing and duration can be freely configured.

The sample code provided in 'Vibration measurement and monitoring system using Raspberry Pi products.'

Machine Condition Monitoring System

Consition monitoring system reads measurement data, calculates RMS. By customizing this program, you can implement condition monitoring tailored to your environment, such as monitoring only specific frequency bands or acquiring indicators other than RMS.

The sample code included in this page.

Monitoring Application

Monitoring application sends aggregated results and alerts via MQTT messages for web-based monitoring.

The sample code provided in 'Vibration measurement and monitoring system using Raspberry Pi products.'

Documentation

| Document | Description |

|---|---|

| ISO 20816-Based Machine Condition Monitoring System User Guide (PDF, 1.1MB) | A guide for building and utilizing this system. |

Program

| Source Code | Description |

|---|---|

| ISO 20816-Based Machine Condition Monitoring System Source Code (ZIP, 58KB) | Includes programs for system implementation and customization. |