Sensing Solutions for Machine Health Monitoring

Case 1: Evaluating Vibration Impact in Factories

In factories producing precision components or in cleanroom environments, vibrations from air-conditioning systems or surrounding equipment can affect product quality. To identify such subtle vibration impacts, high-precision sensors are essential.

Epson's low-noise, low-power quartz accelerometers are ideal for vibration measurement in factories. We also provide system configuration examples and sample code for VC (Vibration Criteria) commonly used in precision equipment vibration assessment.

What is VC (Vibration Criteria)?

Before installing precision equipment, it is necessary to evaluate the vibration at the installation site to ensure the equipment can operate properly. VC evaluation is a widely used method for assessing environmental vibration.

The permissible vibration criteria for precision equipment are expressed as VC levels, and the installation environment must maintain vibration below these levels.

Using Epson accelerometers, you can determine VC levels for environmental vibration and implement vibration impact assessments and mitigation measures.

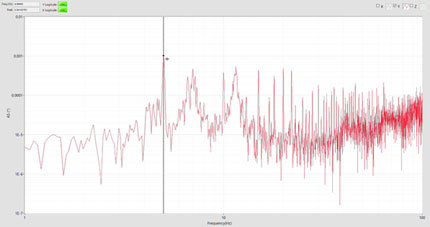

Furthermore, Epson accelerometers have self-noise levels below VC-G (see figure), enabling compliance with the most stringent environmental evaluations.

Tripartite Graph

VC levels can be calculated and displayed from accelerometer measurement data. By computing the one-third octave band of RMS velocity from measured vibration data, VC levels are determined. Results are shown as a tripartite graph. For example, if the vibration peak lies between VC-B and VC-A, the VC level is judged as VC-A.

VC Levels and Equipment Examples

When using precision equipment, environmental vibration must be kept below the permissible vibration criteria (VC levels), which vary by equipment type. The table below shows typical reference values:

| VC Level | Example Equipment |

|---|---|

| A | Proximity projection aligner, optical microscope (400x) |

| B | Stepper (3µm linewidth), optical microscope (1000x) |

| C | Stepper (1µm linewidth), image inspection system (≥1000x) |

| D | Stepper (<1µm linewidth), SEM, TEM |

| E | Semiconductor lithography equipment (nm level), laser interferometer |

| F | Extremely quiet research spaces (difficult to achieve in cleanrooms) |

| G |

Note: These values are for reference only. Please check the specifications of your equipment for details.

Recommended Products

Epson's quartz accelerometers enable simple, compact measurement systems with low power consumption and digital output.

Key Features of Epson Quartz Accelerometers:

- Compact and easy to install

- Low power consumption for easy power supply

- Extremely low self-noise, suitable for VC-G level evaluation

For data sheets or purchase inquiries, please contact us via the inquiry form.

Measurement Tools and Examples Configurations

For easy evaluation of sensors using your PC:

For building a measurement and remote monitoring system using Raspberry Pi:

For building a VC evaluation vibration measurement and remote monitoring system:

Case 2: Monitoring Equipment Condition

In production environments, equipment failure or downtime can lead to significant losses. Predictive maintenance through routine diagnostics is essential to prevent such issues. One effective method is vibration monitoring.

Epson's high-precision sensors can detect subtle vibration changes, enabling early detection of abnormalities in rotating or linear motion equipment, contributing to quality stability and productivity improvement.

Recommended Products

Epson sensing devices enable simple, compact measurement systems with low power consumption and 3-axis digital output, making them ideal for continuous monitoring in limited spaces inside factories or equipment.

Key features of Epson quartz sensors:

- Compact and easy to install

- Low power consumption for easy power supply

- Waterproof and dustproof units (M-A542, M-A552)

ISO 20816-Compliant Vibration Sensors

ISO 20816 (formerly ISO 10816) defines methods and diagnostic criteria for machine vibration monitoring. Epson offers vibration sensors with velocity/displacement output compliant with this standard.

Recommended sensors for predictive maintenance include:

Accelerometers

For monitoring large, slow-rotating equipment, high-precision accelerometers capable of detecting low-frequency vibrations are recommended.

IMU (Inertial Measurement Unit)

IMUs measuring 3-axis acceleration and 3-axis angular velocity can also be used for condition monitoring.

For data sheets or purchase inquiries, please contact us via the inquiry form.

Measurement Tools & Example Configurations

Vibration Sensors / Accelerometers

For easy evaluation of sensors using your PC:

For building a measurement and remote monitoring system using Raspberry Pi:

Additional reference resources are also available for product integration.

IMU (Inertial Measurement Unit)

For customers who want to use IMU (Inertial Measurement Unit)

Use Cases

Vibration Analysis Technology

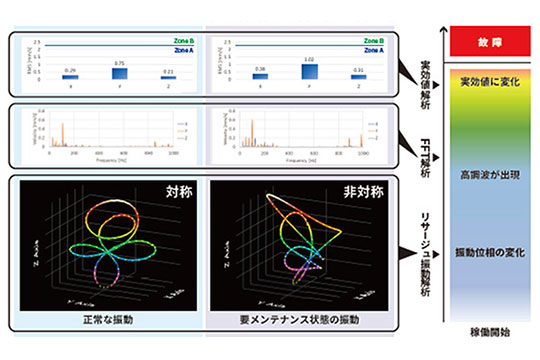

Epson has developed proprietary vibration analysis technologies for predictive maintenance, leveraging high-precision, 3-axis synchronized quartz accelerometers:

- Deep Learning-Based Anomaly Detection (Joint research with Osaka Metropolitan University)

- Precision Lissajous Analysis for 3D visualization of equipment vibration

For details, see technical papers.

Contact Us

For product purchases, inquiries, or documentation requests, please contact us via the inquiry form.