Our Value

Epson has been a leader in the crystal device market since the inception of our first quartz wristwatch in 1969 Our enduring success stems from a steadfast commitment to in-house production, spanning from the procurement of precise raw crystals to the integration with ICs and oscillators. Rooted in our philosophy of efficient, compact, and precise innovation, we continue to accelerate our contributions to the next chapters of a smart society. This encompasses but is not limited to key domains such as IoT, high-speed and high-capacity communications networks, and automotive safety. The widespread adoption of our crystal devices across varied sectors serves as a tangible testament to the influence of our efforts.

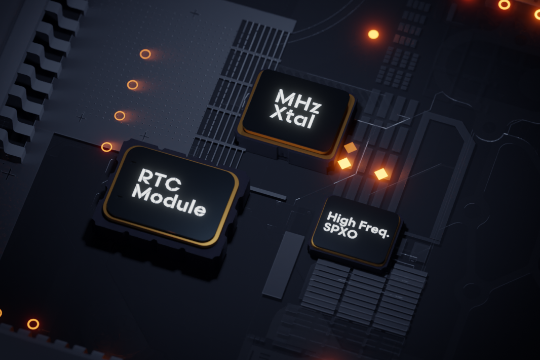

A Philosophy of Efficient, Compact, and Precise Innovation of Crystal Devices

Efficient - Reducing power consumption

Epson Crystal Devices consume minimal power thanks to in-house IC circuit technology that takes full advantage of the characteristics of quartz crystals. Our low-power devices are built around our unique power-saving and control technologies, helping to limit the power consumed by the systems in which they are used.

Compact - Miniaturization

Epson employs its photolithography process on the wafer level to increase processing accuracy and produce ultra-small crystal chips with uniform characteristics.

Demand for smaller IoT devices has been consistently increasing as the smart society has gained traction. We are helping to meet this demand with a lineup of compact, low-profile crystal devices that are specifically suited for such devices.

Precise - Higher accuracy and precision

Epson Crystal Devices boast high stability due to our advanced and precise production technology, offering compact and stable operation with minimal noise and heightened sensitivity which results in exceptional performance. Furthermore, these devices promise to enhance the accuracy of customer devices and facilitate automation across a range of applications, thereby contributing to the advancement of faster, higher-capacity next-generation communication systems.

Commitment to Quality

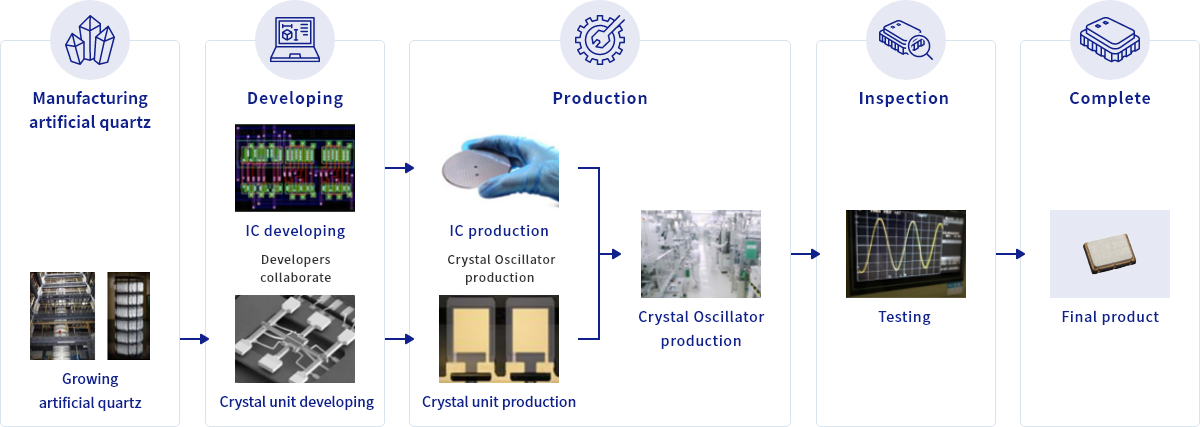

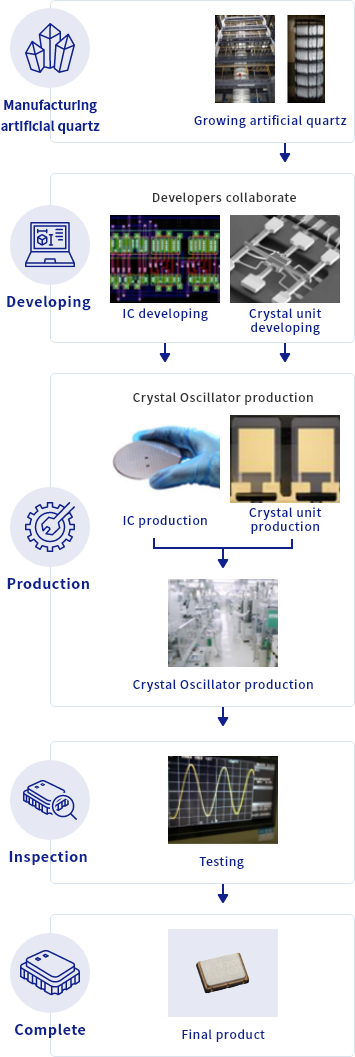

Synthetic crystal manufacturing process

High-Quality Synthetic Crystals

To manufacture high-quality synthetic crystals, strict control of the raw materials, seed crystals, autoclave performance, and manufacturing conditions are necessary. Highly trained and experienced engineers play a crucial role in keeping the equipment in ideal condition. Among these factors, the autoclave chamber stands out as the most critical element. Maintaining high temperature and pressure safely for up to six months is imperative, making even the slightest distortion of the sealing surface unacceptable. After being used, precision correction of the sealing surface is essential, requiring micron-level accuracy and ultimately, hand-finishing touches. This aspect underscores the necessity for master craftsmanship which allows Epson to successfully grow and manufacture synthetic crystals for its crystal devices.

In-House Production of Semiconductors and Crystals

Epson designs and manufactures both crystal units and oscillator ICs. Having engineers from both the crystal side and the IC side work together in product development enables us to produce high-quality products that fully exploit the characteristics of quartz crystals.

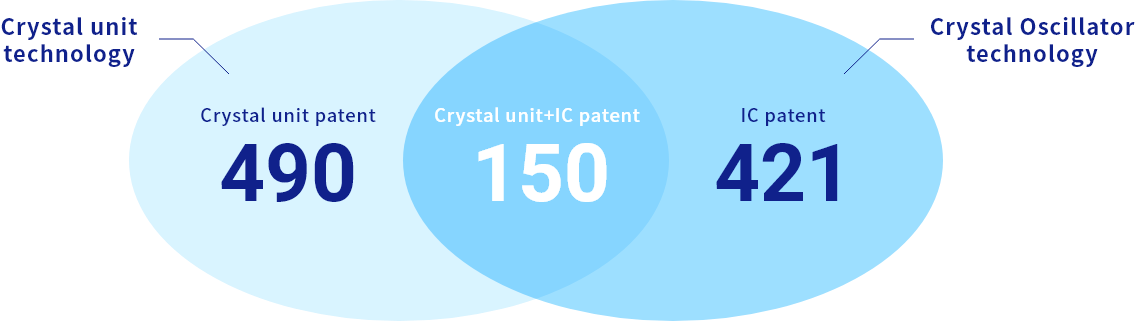

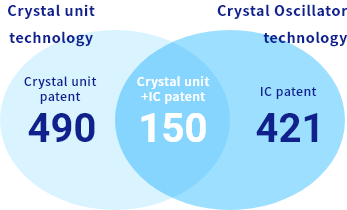

No. 1 in Patents in the Crystal Device Industry

As of February 2022, Epson ranked first in the crystal device industry regarding the number of patent applications filed, both domestically and internationally, concerning Epson Crystal Devices. These patents encompass a range of technologies related to crystal units and oscillator ICs and they play a crucial role in sustaining stable business operations globally.

Sales Support System

Worldwide Support System

Epson has 7 countries and areas of sales companies overseas. Those sales companies work closely with each other to form a worldwide support system. For example, from Germany supports Europe area, middle east Asia and Africa, from Singapore supports Asia and Oceania. Even if the places of customers developing and manufacturing apart, our sales companies will support with each other and progress smoothly.

Epson's sales offices are located globally, specifically in 7 countries. These offices work closely with each other to form a worldwide support system. Even if our customers and partners are not located close to one of these offices, Epson still commits to supplying top-tier support by ensuring we can provide the best product and overall experience to whomever we're engaged with. We pride ourselves on our customer service and support.

Services Homogenization and Multi-Channelization

Not only do we strive for excellence in directly supporting our customers, but we also place that same emphasis on supporting our distributors and business partners as well. By holding regular trainings, our distributors and business partners are consistently updated about the value Epson can offer to their customers. This allows the distributors, business partners and customers to ultimately have a better understanding of Epson's business which in turn, leads to more successful business operations for all parties involved.

Solving Societal Issues

Epson technologies play a significant role in addressing societal challenges. Despite the strain on electronic device supplies, we have maintained a focus on providing products crucial for tackling societal issues. For instance, our TCXOs were integrated into temperature monitoring modules used in transporting Covid vaccines during the pandemic. These advanced devices facilitated precise temperature measurements and tracked the location of vaccine transport boxes, ensuring the safe and reliable distribution of vaccines worldwide. Epson compact, low power, high precision devices will continue to enhance safety and security by supporting applications requiring safety management and efficient infrastructure operation.

Environmental Initiatives

Epson publicly committed to becoming carbon negative and underground-resource*1 free in Environmental Vision 2050. The use of renewable electricity was a key means by which we sought to reach our goal of decarbonization. In March 2021, we switched to 100% renewable electricity to meet the electricity needs at all Epson Group sites in Japan*2. In December 2023, we completed the switch globally.

In addition to sourcing renewable electricity, Epson will promote the broader adoption of renewable electricity, including by generating more of its own power and by supporting the development of new power sources through co-creation. We will reduce the amount of energy associated with production and product development and will continue to pursue further advances in resource circulation to attain the goal of becoming carbon negative.

*1 : Free of non-renewable resources such as oil and metals

*2 : Excludes some sales sites and leased properties where the amount of electricity consumed cannot be determined